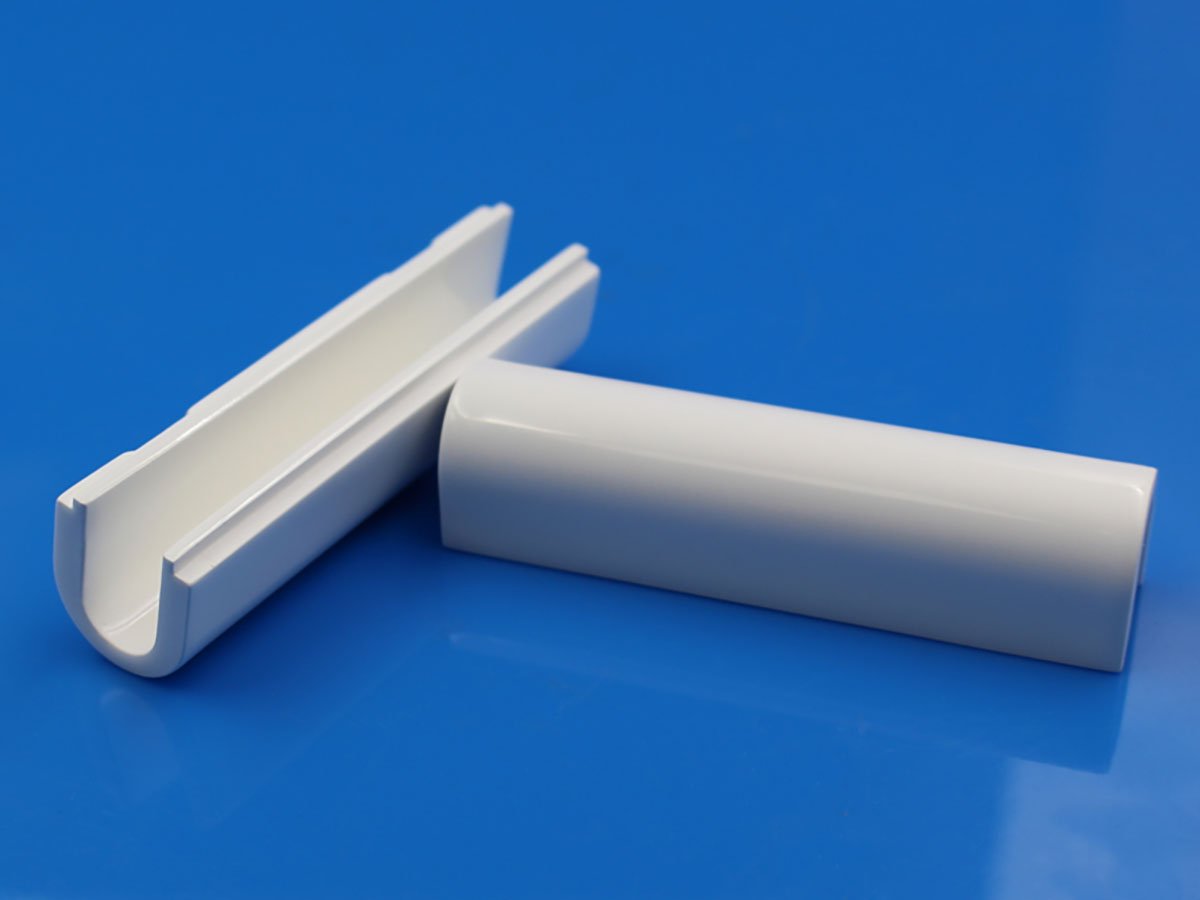

Ceramic Reflector

Optinnovate ceramic reflectors nearly perfectly diffuse reflection and high reflection efficiency are effectively exploited in laser systems with laser hosts having pump bands in the 500 nm to 1200 nm spectral range.

We can machine or grind ceramic reflectors against the customer’s drawing. Quantities range from prototype to production quantities. Glazing protects the surface in preventing adhesion of impurities and primarily ensures leak tightness of the reflectors.

Optinnovate ceramic reflectors can has a glazed surface. It is impervious to coolants and the contaminants that may be circulating with them. It is well suited for use in compact, high energy flooded cavity laser heads.

Ceramic Reflector material properties:

- Bulk density (fired), Mg/m3:3.1

- Color: White

- Porosity (apparent), % nominal: 22

- Flexural strength (ASTM C1161, 3-point), MPa: 170

- Thermal expansion coefficient

200-500C, 10-6/C 7.9

200-1000C, 10-6/C 9.0

Ceramic Reflector features:

- Compared to metal reflectors, ceramic units offer higher reflectivity and therefore enhanced laser power

- Surfaces can be sealed and coated with a solarization-resistant glaze to give high bulk reflectivity

- Resists chemical attack

- Controlled porosity

- Has high strength

- Good thermal conductivity

- High electrical resistivity